-

Content

14 -

Joined

-

Last visited

Never -

Feedback

0%

Content Type

Profiles

Forums

Calendar

Dropzones

Gear

Articles

Fatalities

Stolen

Indoor

Help

Downloads

Gallery

Blogs

Store

Videos

Classifieds

Everything posted by slots

-

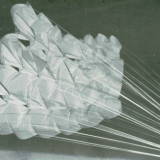

Despite all their draw backs, Capewells did offer the advantage of being able to convert a conventional rig to a cut away rig without any permanent change to the harness. This could be done by using a “clip on Capewells” These consist of a pair of additional female Capewells, some tape (type 11?) and a pair of connector links. See photo clip on Capewell. With the connector link removed, the loop end of the webbing can be threaded through the main male Capewell, doubled back underneath and then locked in place by the connector link. See photo clip on Capewell attached to main riser. The main riser is then attached to the harness in the normal way and can be detached without any interference, though a couple of hand stitches should be used where shown to stop the clip on Capewells falling over the main ones after the cut away canopy has been released. See photo clip on Capewell on the rig. This system was used to test all my home made canopies and always worked without any problems. I should add however that as only the very thin (type 11?) webbing can be used; all my test canopies were deployed by static line. Whether this thin webbing would survive many terminal openings is something unknown.

-

No, The right Wally is at it really appeared, the wrong wally is the same picture flipped. As I said "Photos taken from above did not read correctly unless reversed and this put the jumper OVER the canopy instead of beneath it."

-

I don't know the current rules having left the sport some 16 years ago. At the time the British Parachute Association required all parachutists to wear two parachutes made by "an approved manufacturer”. As I was not an approved manufacturer, not a rigger but just a Do It Yourself bloke, for quite some time I had to use whatever I was testing as a third canopy in a cut away rig. All together I made eleven parachutes, none of them suitable for production at the time they were designed. i.e Slots might have been several years earlier. The other parachutes of mine that were perhaps interesting where my three “Parashapes”. These were an attempt to copy the hot air balloon special shapes for advertising purposes. Parashape 1 is “WALLY”, made for the Wally Gubbins videos made by Leo Dickinson. Foolishly I made WALLY to read correctly from below and since it was far too dangerous to land it, taking photos from below was nearly impossible. Photos taken from above did not read correctly unless reversed and this put the jumper OVER the canopy instead of beneath it. Parashape 2 is The Olympic Rings, made with the intention of stealing a little bit of the Americans limelight I knew they would achieve at the 1988 Olympics. This did not happen as this was a very difficult parachute to get to fly right, several modifications being required. When it was right it still had a very high malfunction rate and we ran into copyright problems. Despite the fact that it oscillated wildly swinging the test parachutist through quite a large arc (it had to have VERY long lines) it was once landed safely. Parashape 3 was made with the intention of having a safe Parashape that could be landed in reasonably calm conditions. Looking for a suitable shape I finally decided on the either the Volkswagen logo or a POLO mint. (If POLO mints are unknown to you, they are a small round sweet (candy?) with a hole in the middle). A photo of a 6’ diameter model made to test my ability to add the words “POLO” is attached. After the copyright problems with the Olympic Rings, VW and Nestles (who made POLO mints) were approached for permission. Nestles declined, VW gave ascent. This was handy as the VW logo reads correctly from above and below. I made thirty odd jumps on Parashape 3, safely landing on all but one occasion when jumping in high wind for Leo to film. All the Parashapes were single skin canopies, but a second skin was added to Parashape 3 to see if it was possible to reduce the bellowing between the rigging lines to clean up the shape. Since this second skin had to have holes to let the air in, where these coincided with the drive or turn slots it gave the appearance of having eyes (see photo).

-

I was very interested to read Jerry Baumchen’s account of the LeMoigne idea of using formed panels to direct air out of a round canopy, and how Dan Abbott designed a “copy” of the LeMoigne principle using flat panels. Back in the 80’s I gave a lot of thought to the radical difference between a flat circular canopy and a LeMoigne type. Realising that the shaped panels not only provided drive but also lift I wondered if there was a way to have more of these shaped panels. Not on a round parachute there wasn’t, but parachutes don’t have to be round do they? I came up with the idea of getting shaped panels out of flat material on a single layer square parachute, first of all by also using the Derry Slot principle, but in a horizontal plane rather than near vertical. The first one was made of just five flat panels as shown in the drawing, Fig 1. All the lines shown in the drawing are where the panels are reinforced with tape. Each panel is joined to the next one ONLY where the arrow heads are shown, and on the curved ends which formed the stabilisers. The black dots mark the rigging line attachment points. The front (upper) four panels only have rigging lines on the leading edge which is pulled down, but the trailing edge of the panel in front billows upward to make a shaped panel like the LeMoigne type, but from flat material more on the Derry Slot principle. This parachute became known as Slots, later called Slots 1. It was twice dropped from 500 feet with a sand bag load, then live static line jumped from 4,000 feet and landed safely first jump. I had over erred on the side of caution and Slots 1 was in fact far too big so a smaller Slots 2 was built using six panels, four lift panels and two flat stabiliser panels. A further development was Slots 3 with six panels exactly as Slots 2, but these panels were only joined to each other directly at the stabilisers. They were joined indirectly by a 6 inch tape at the entire mid canopy line attachment points. Slots 3 was very successful being cleared in the U.K. for use as a main parachute by D licence holders. It was used many times for display purposes into restricted areas without any problem. It was perhaps 20% faster than a PC, turned quicker and only had about 60% of the bulk. Slots 1, 2 & 3 were the first parachutes I made. Slots 1 was first jumped in April 1980, Slots 2 was first jumped in November 1980 and Slots 3 in October 1981. Those dates tell you why you have probably never heard of them. They never went into production because Ram Air parachutes had already taken over. Slots 3 was loaned to Rigging Innovations for evaluation and later to Pioneer Aerospace. There are two Slots 3 canopies still in occasional use such as at the Vintage Weekend at Teuge in the Netherlands every year and I understand a rigger in Canada is building two more for fun use. Dick Gays, U.K.

-

Early Old Vintage Parachute Test cica 1920's

slots replied to davidlayne's topic in Skydiving History & Trivia

Does this count as the earliest base jump?